Module for the formation of truck battery with acid recirculation in a close loop cycle

This is the innovative system to reduce time in formation cycle of the industrial elements for these reasons:

• the use of a low density acid enhances the electro chemical transformation of the paste, granting –with the same level of Ah used– a higher % of PbO2

• The continuous circulation of acid, helps the release of gas molecules on plate’ surfaces, optimizing the charge efficiency.

• The acid circulation grant his constant and correct temperature inside the element, avoiding the risk to damage separators and plates.

So we can charge the elements pushing with high current and reducing the charging times.

The heat, the gases and aerosol are took away by the circulation acid proces, while the cells are filled at the beginning of the proces, with the selected acid density/formation cycle on the main management plc. At the end of the charge, the correct final density of acid will be inserted into elements.

Is suitable for all companies that have space or not in the formation area. Also if you already have a close loop formation, but you want to find an other supplier, reliable, competent and cheap or simply your necessities are small, here we are.

Mainly we have two models of module:

• Type BFTCL_B is a base module for the companies that already have the possibility to connect it to a main network for acid, cool water, demi, air suction

• Type BFTCL_C that is the standing alone“ALL-IN-ONE” module, which include all the necessities with proper tanks, coolings and scrubbing systems

The module BFTCL is self working, autonomous, and engineered to prevent the increase of the acid that (in competitor’s system) normally comes and is around 30%. This avoid the re-titration of it and where not possible, to collect a huge quantity of diluted acid.

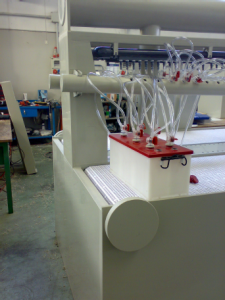

Technical descripiton module BFTCL6_120B:

Module composed of 6 positions. In each module is possible to conect max 120 bateries per formation cycle that can be from 6 to 9 hours. The batteries should be displayed on raw of 20. Totally the module BFTCL6_120B can accept 3+3 raws.

Materials used:

AISI 316L stainless steel massive frame where the tank, the conveyors, the manifold to supply the

elements, the electrical cabinet are installed.

Manifold supply of the acid to elements, including filling plugs, and pipings Electrical cabinet and panel to manage and control all the system, safeties and software for the

process, with recipes storage and data acquisition.

The module BFTCL6_120 B is composed as follows:

• PPS tanks and pump for acid circulation, piping and valves, filters and all related parts.

• Cooling element, with temperature and concentration control devices, level controls

• nozles to connect to all utilities like water, acid and air.

• boxes with cables to be connected to elements.

The module need to be connected to main supply network of:

• Concentrated acid (1.840 gr/l)

• Demineralised water

• Cooled water T max 28°C, Q. +- 5m3/h

• Air suction (6.000 m3/h)

• Rectifiers cables to local boxes

• Relais on rectifiers to link to module management software

Acid and water section optional

The module can be stand alone, all in one. This means that we can place this module where you want, and sometimes fill the acid and deionized water tanks; connect with the external environment for the air that is cleaned on the module scrubber.

This section is composed:

Storage tank for acid concentrated, diluted, water /Piping with valvs and all related pump / Collecting tray / Distribution pipeline / Control sensors, levels allarms / Software / Aspiration and scrubbing